I Didn’t Know I Could Do This

If you saw my earlier blog you saw this blade. BUT…

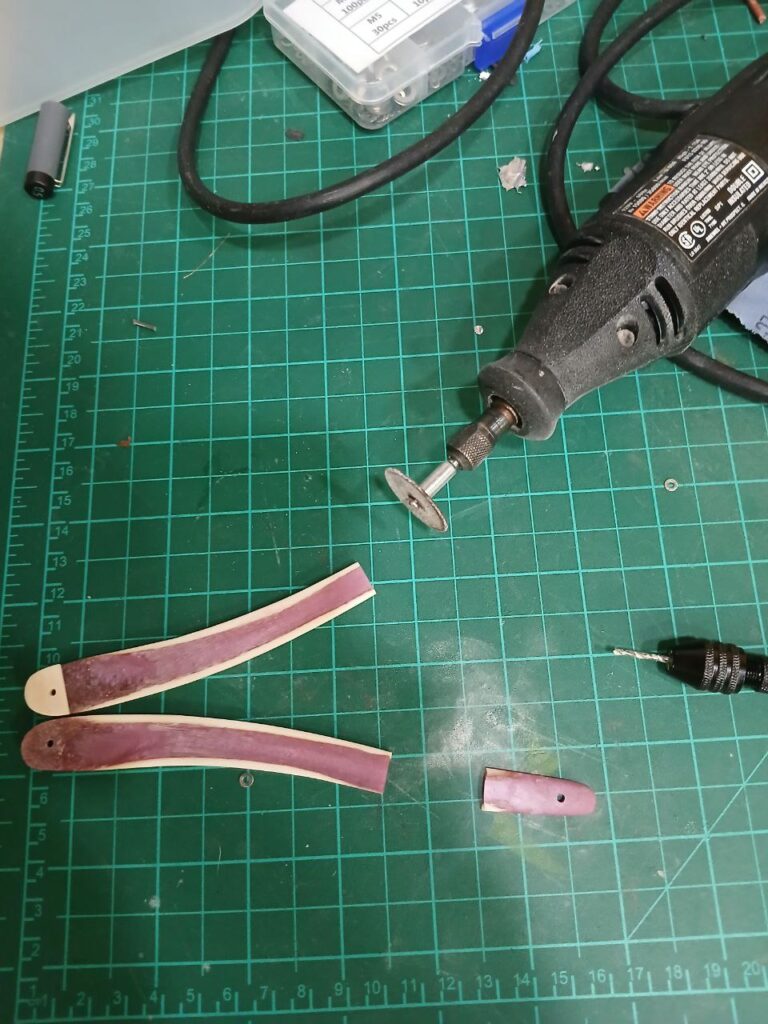

The resin was too thing and snapped, so I thought I would try a repair. I cut both pieces to size.

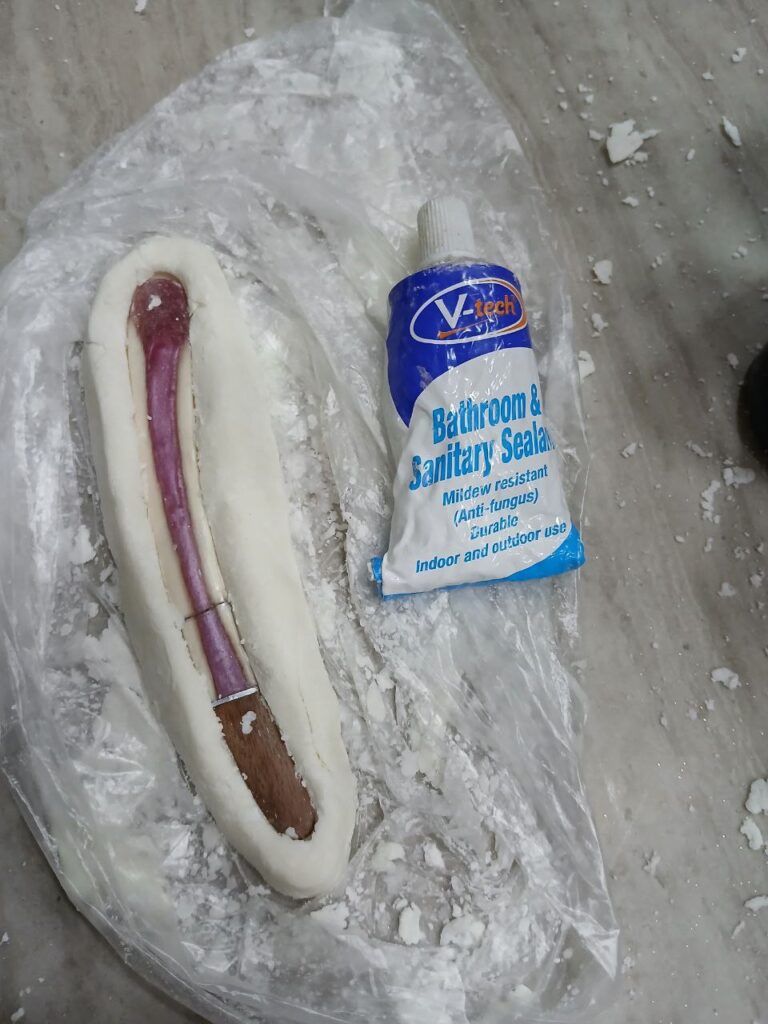

Then I fitted them with walnut tops, but this one was still too little bone and too much resin. So it snapped in my stress test. So I used it to make a new silicone mold (cornstarch and silicone cauking) and…

picked a new bone from the 3 or 4 deer worth of bones I’ve found out here in the country.

I picked one and started cutting and shaping a new bone by hand. This one looks good.

I ground the new bone down to match the previous one.

I used the mold I made to fill the empy parts with resin and mermaid dust.

I added metal accents and capped and added the walnut. Now I just have to pin, drill, and pin again.

And the End Product!

It’s not perfect… but it’s REALLY close.